Brand: XURON

If you are searching for a cost-effective and printing that is versatile is textile, take a good look at the XURON Textile DTF Transfer Printing Machine.

This product this is certainly DTF that is revolutionary Direct-to-Film printing technology to produce top-quality and vibrant designs for a lot of different textile surfaces, including cotton, polyester, in addition to material.

The XURON Textile DTF Transfer Printing Machine makes it easy to produce customized designs and patterns which are certain to wow along which consists of powerful printing brain and intuitive program that is individual is graphical. The merchandise provides accuracy this is certainly information that is exemplary providing you the capability to bring your innovative vision to life whether you may be printing onto t-shirts, caps, bags, or nearly every other item that is textile.

The choice that is large of highlights of the XURON Textile DTF Transfer Printing device is its versatility. Become able to print onto a number that is genuine is wide of, it is easy to meet certain requirements of an individual's clients and expand your products or services offerings. And due to the compact and design this is certainly portable this revolutionary product fits easily into any workplace, which makes it ideal for both small-scale and textile this is certainly operations that are commercial.

60cm DTF machine |

||

Nozzle Type |

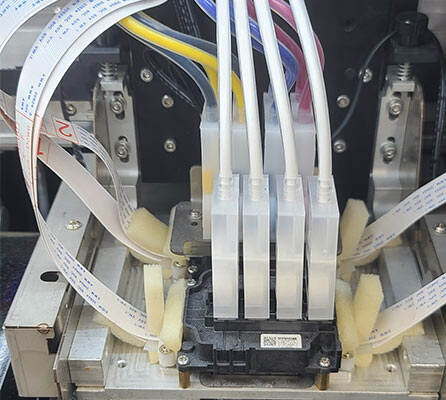

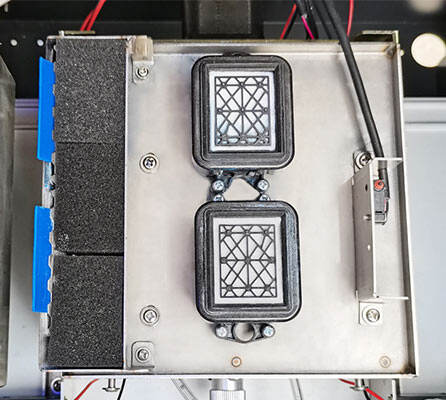

2 original Epson I3200 |

|

Nozzle Type(interweave printing program) |

1 original EPSON I3200(8)-A1

1 original EPSON I3200(4)-A1

|

|

Printing Speed |

4 pass 720*1200 :High speed mode 15m²/hour

6 pass 720*1800 :HD mode 10m²/hour

8 pass 720*2400 :HD mode 8m²/hour

|

|

Printing Speed(interweave printing program) |

4 pass 720*1200 :High speed mode 25m²/hour 6 pass 720*1800 :HD mode 20m²/hour |

|

Color Mode |

CMYK+W |

|

Print Format |

600mm-650mm |

|

Media Transfer |

Damping paper/tension paper |

|

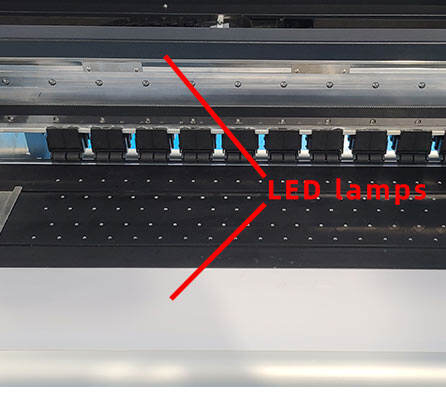

Heating Equipment |

Front, middle and back three-stage heating |

|

Power Supply |

110V/220V 50-60Hz |

|

Power |

1kw |

|

Working Environment |

Temperature 20-28℃ Humidity 70% |

|

Ink road system |

Automatic ink supply, Constant pressure circulation system |

|

Weight |

160KG |

|

Package Dimensions |

181*94*136cm cbm:2.31 |

|

Shake powder machine |

||

Power |

≈2KW |

|

Shaking Powder |

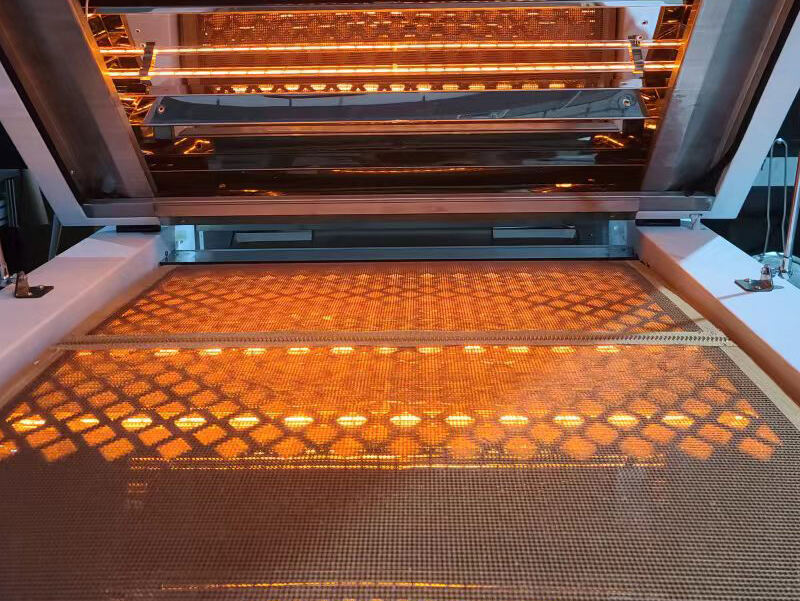

Motor vibration, automatic powder return-free |

|

Heating Method |

Back baking and front baking Fast constant temperature heating |

|

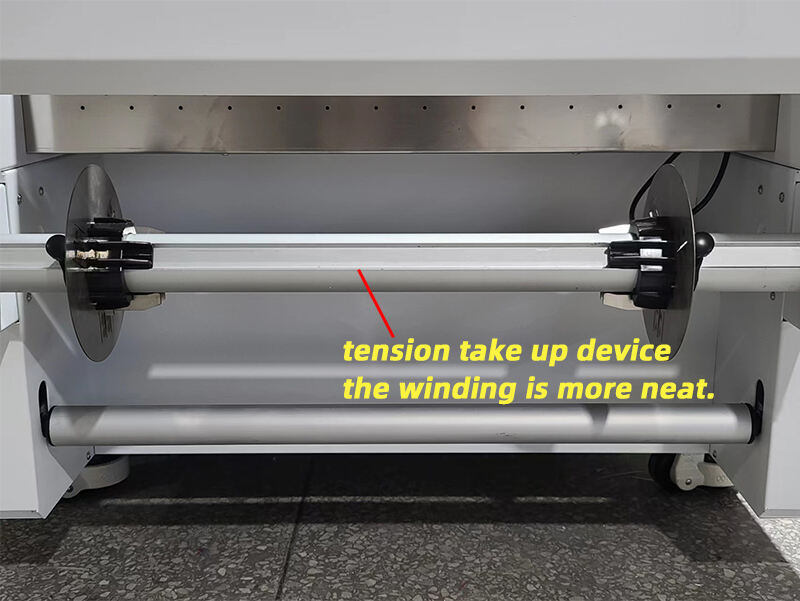

Take-up and Feed Film |

Constant tension automatic induction system |

|

Operation Mode |

Manual control/Auto control |

|

Mesh Belt |

Drum suction operation mesh belt |

|

Automatic Deceleration of Film Cutting |

Prevent deformation of heating film |

|

Method of Dusting |

Constant weight automatic sensing |

|

Machine Weight |

240KG |

|

Package Weight |

347KG |

|

Package Dimensions |

193*114.5*110.5cm cbm:2.44 |

|

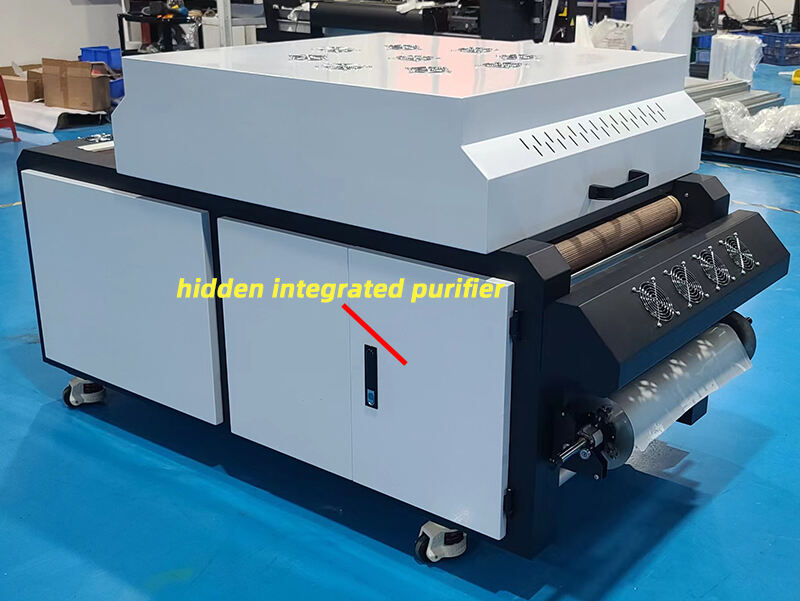

Configuration |

With All-in-one smoke purifier |

|

TOTAL PRINTER WITH SHAKE MACHINE |

||

Cover Area |

108*350cm |

|