Brand: XURON

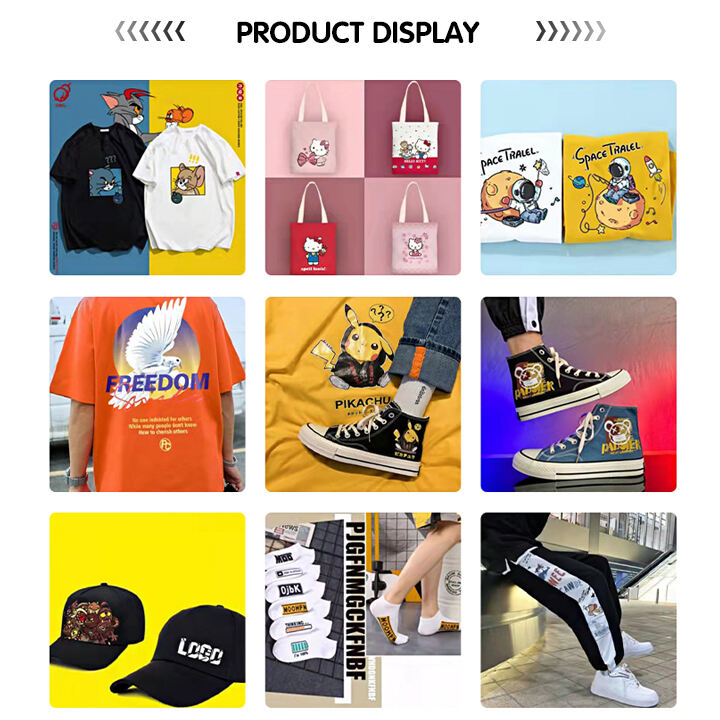

Introducing the innovation that is latest in heat transfer printing technology – the XURON DTF Heat Transfer Advanced Printer Machine. This high-level publishing machine has everything you need to produce seamless and high-quality publishing designs on a number of fabrics whether you're a passionate DIY lover or a professional printer company.

The XURON DTF Heat Transfer Advanced Printer Machine is made with simplicity of quality while making use of in your mind. It's designed with the DTF this is certainly latest (Direct to Film) printing technology, letting you definitely achieve vibrant and accurate colors together with your designs. The product works together a number of materials, including cotton, polyester, silk, and even more, making it a good choice for your printing needs.

Forget the hassle of conventional publishing methods – the XURON DTF Heat Transfer Advanced Printer Machine is made to create your publishing experience seamless and enjoyable. The unit is sold with a user-friendly LCD screen that gives you control that is complete your designs, rendering it easy to adjust the publishing settings and monitor the publishing progress.

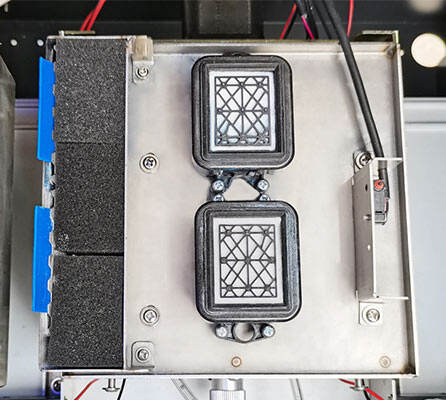

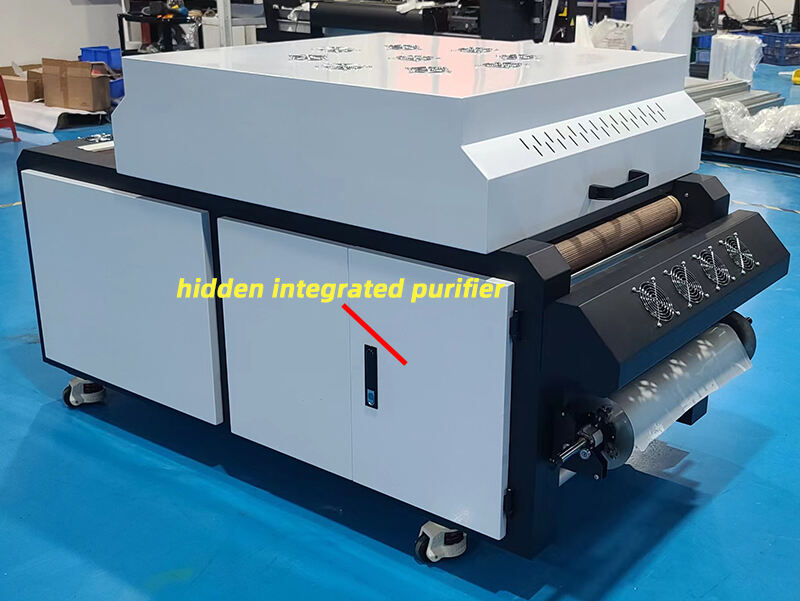

One of several unique options that come with the XURON DTF Heat Transfer Advanced Printer Machine is the fact that it boils down with a vacuum cleaner system that is built in. This method really helps to make sure that your movies are positioned firmly from the publishing surface, minimizing the risk of any movement that is undesirable the publishing procedure.

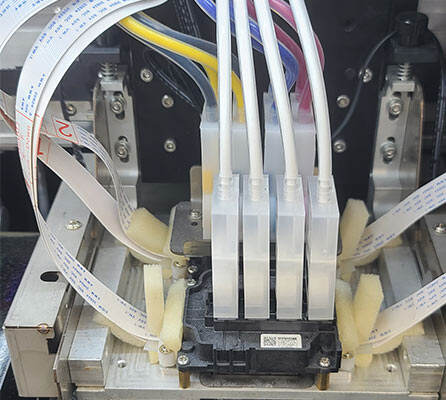

The XURON DTF Heat Transfer Advanced Printer Machine may also be built with an ink that is state-of-the-art that produces high-quality and colors that are vibrant together with your designs. The ink system was made to be durable and long-lasting, making sure your images look great even with multiple washes.

Finally, the XURON DTF Heat Transfer Advanced Printer Machine is designed to be versatile and practical. Its compact and lightweight, making it easy to move and store if not being used. Also, it comes down by having a selection of add-ons and attachments which will make it very easy to print on a range this is certainly wide of.

60cm DTF machine |

||

Nozzle Type |

2 original Epson I3200 |

|

Nozzle Type(interweave printing program) |

1 original EPSON I3200(8)-A1

1 original EPSON I3200(4)-A1

|

|

Printing Speed |

4 pass 720*1200 :High speed mode 15m²/hour

6 pass 720*1800 :HD mode 10m²/hour

8 pass 720*2400 :HD mode 8m²/hour

|

|

Printing Speed(interweave printing program) |

4 pass 720*1200 :High speed mode 25m²/hour 6 pass 720*1800 :HD mode 20m²/hour |

|

Color Mode |

CMYK+W |

|

Print Format |

600mm-650mm |

|

Media Transfer |

Damping paper/tension paper |

|

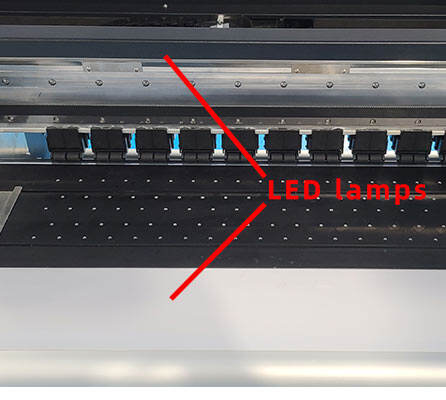

Heating Equipment |

Front, middle and back three-stage heating |

|

Power Supply |

110V/220V 50-60Hz |

|

Power |

1kw |

|

Working Environment |

Temperature 20-28℃ Humidity 70% |

|

Ink road system |

Automatic ink supply, Constant pressure circulation system |

|

Weight |

160KG |

|

Package Dimensions |

181*94*136cm cbm:2.31 |

|

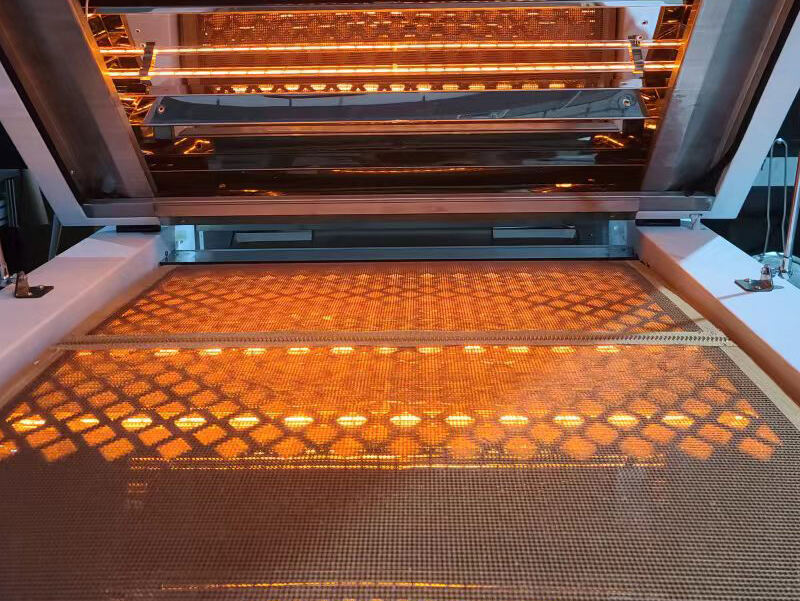

Shake powder machine |

||

Power |

≈2KW |

|

Shaking Powder |

Motor vibration, automatic powder return-free |

|

Heating Method |

Back baking and front baking Fast constant temperature heating |

|

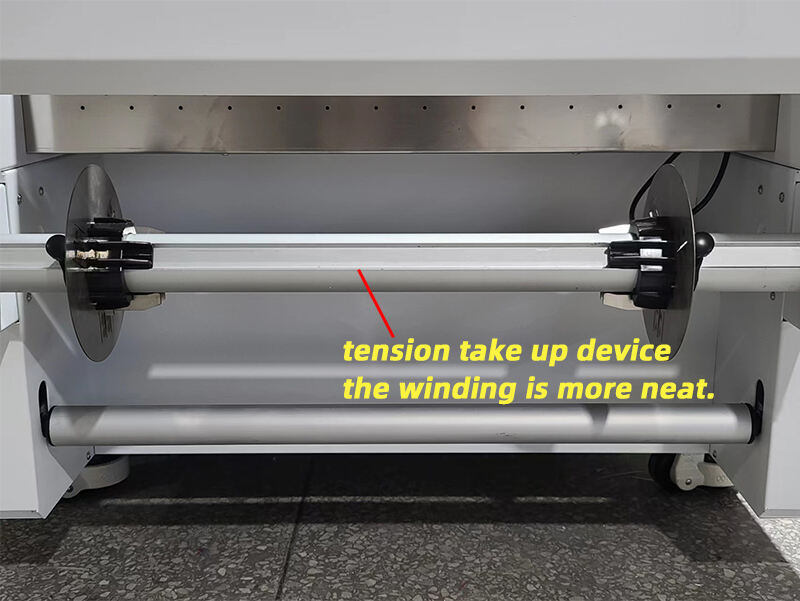

Take-up and Feed Film |

Constant tension automatic induction system |

|

Operation Mode |

Manual control/Auto control |

|

Mesh Belt |

Drum suction operation mesh belt |

|

Automatic Deceleration of Film Cutting |

Prevent deformation of heating film |

|

Method of Dusting |

Constant weight automatic sensing |

|

Machine Weight |

240KG |

|

Package Weight |

347KG |

|

Package Dimensions |

193*114.5*110.5cm cbm:2.44 |

|

Configuration |

With All-in-one smoke purifier |

|

TOTAL PRINTER WITH SHAKE MACHINE |

||

Cover Area |

108*350cm |

|